ISO 9409-1: The interface between robot and tool

Share

ISO 9409-1 is an international standard that defines the mechanical interface between an industrial robot and its tool – for example, between a robot arm and a gripper, vacuum cleaner or welding torch.

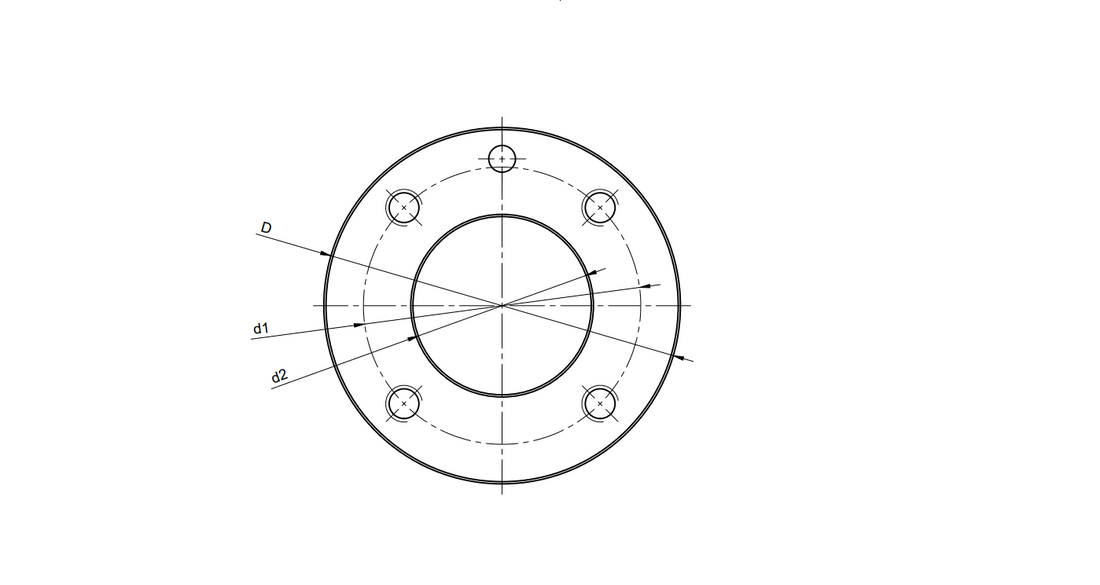

This standard ensures compatibility and interchangeability across manufacturers, as it defines standardized dimensions such as the pitch circle diameter (PCD) , the centering collar , drilling patterns , and the outer diameter of the flange. This allows tools to be mounted quickly and securely on a wide variety of robots – without adapters or special solutions.

Whether it's a small cobot or a heavy-duty robot, ISO 9409-1 makes tool changes child's play. Anyone who thinks about automation in a modular way cannot ignore this standard.

Common flanges and their corresponding dimensions:

| Designation | D - Outer diameter | d1 - pitch diameter | d2 - Diameter of centering collar | l1 - Depth of centering collar | Drilling |

Standard designation flange

|

| [mm] | [mm] | [mm] | [mm] | Number x thread | ||

| ISO 40 | 40 | 31.5 | 20 | 2.5 | 4 x M6 | ISO 9409-1-31.5-4-M6 |

| ISO 50 | 50 | 40 | 25 | 3 | 4 x M6 | ISO 9409-1-40-4-M6 |

| ISO 63 | 63 | 50 | 31.5 | 3.5 | 4 x M6 | ISO 9409-1-50-4-M6 |

| ISO 80 | 80 | 63 | 40 | 4 | 6 x M6 | ISO 9409-1-63-6-M6 |

| ISO 100 | 100 | 80 | 50 | 5 | 6 x M8 | ISO 9409-1-80-6-M8 |

Some robots and their tool flanges:

ISO 9409-1-50-4-M6 : Universal Robots: UR3e, UR5e, UR10e, UR16e; Yaskawa: HC10, HC20, GP-4 to GP20

ISO 9409-1-80-6-M8: Universal Robots: UR20 & UR30, Yaskawa: GP-35

All statements without guarantee.