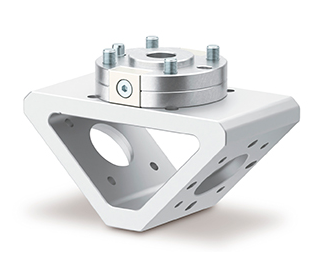

Multitool adapter in robotics

Share

A multi-tool adapter in robotics is a device that allows a robot to use multiple tools at once or to quickly switch between different tools without having to retool the robot arm. This is particularly beneficial in machine loading and component handling as cycle time can be significantly reduced, thereby increasing efficiency and productivity.

In practice, this means that the robot can attach various tools such as grippers, suction cups, screwing tools or measuring instruments directly to an adapter. The multi-tool adapter ensures that the robot switches seamlessly between tools within a work cycle without having to go into a waiting position or change the tool manually. This flexible adaptability is particularly advantageous in the manufacturing industry, as production processes are becoming increasingly demanding and complex.

Some key benefits of using multi-tool adapters in robotics include:

- Shorter cycle times : Since the robot does not have to wait for tools to be changed, it can complete its tasks faster.

- Higher precision : Automated tool changing reduces the risk of human error and ensures consistent precision.

- Lower costs : Optimizing cycle time leads to better utilization of robots and reduces downtime.

- Flexibility : With a multi-tool adapter, a robot can easily switch between different tasks and thus take over a variety of work processes within a production line.

This technology supports the automation and flexibility of production and enables output to be maximized while reducing operating costs.