Also for old bags - grasp monkey gripper for handling bagged goods

palletizing and gripping bags

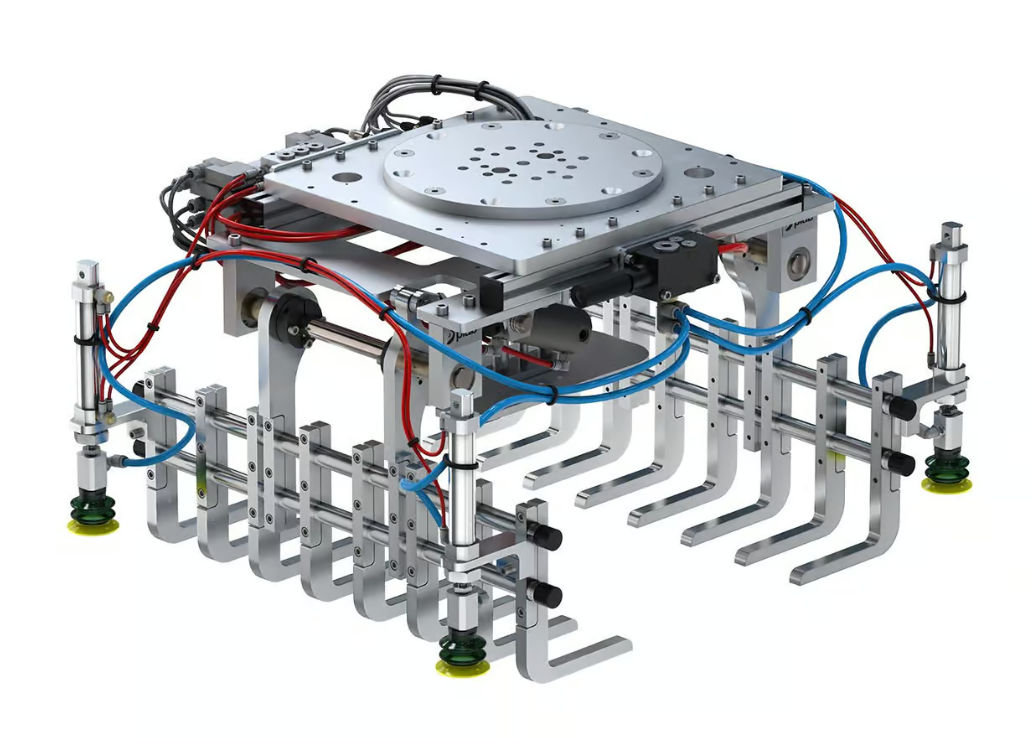

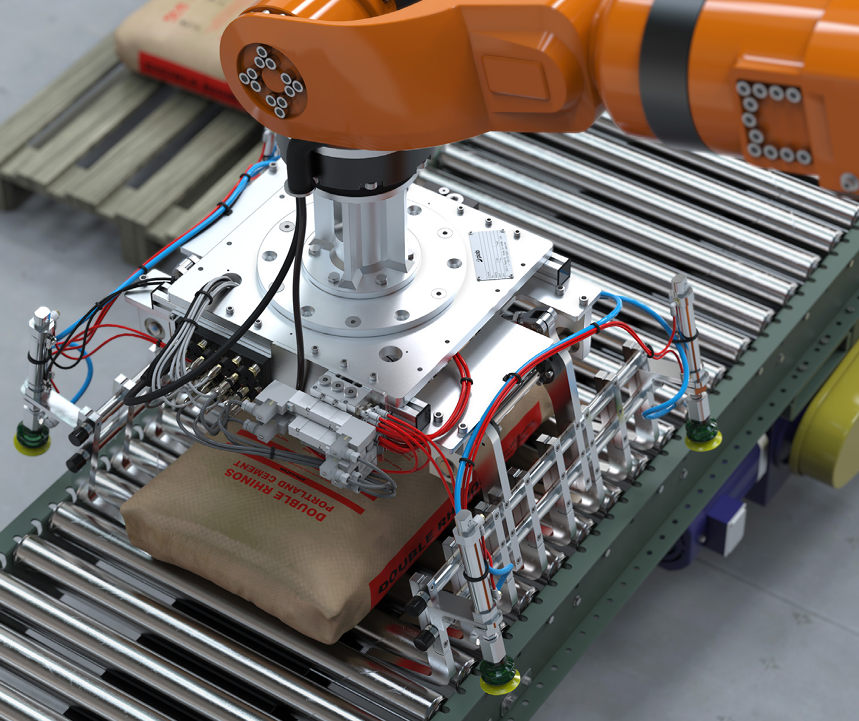

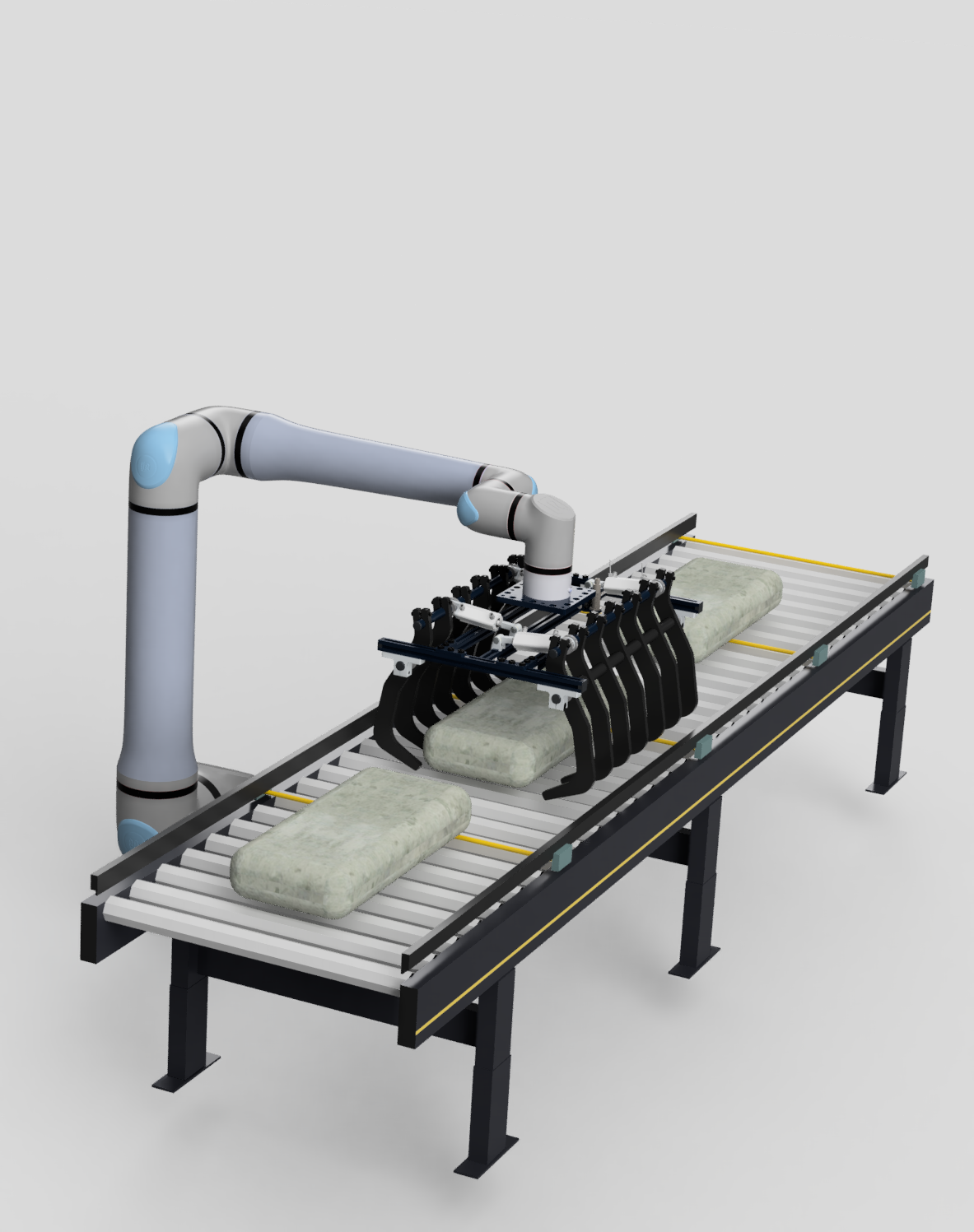

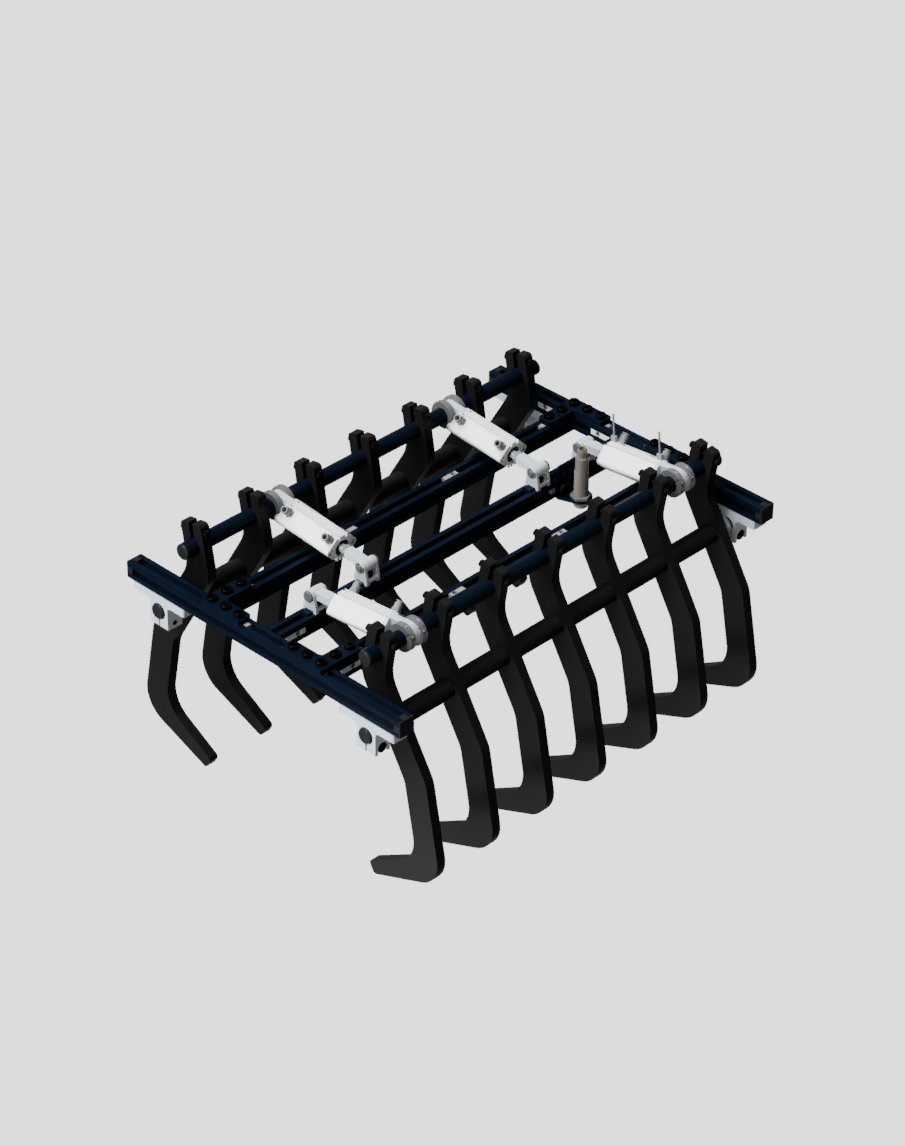

Mechanical grippers for bags are often used when palletizing bags because they ensure precise and reliable handling. Handling bags is a particular challenge due to their irregular shape, often slack texture and sensitive surfaces. Our mechanical grippers for bags offer a precise and gentle solution: they grip the product underneath with specially developed tines and enclose it securely. It is crucial that the gripper is precisely tailored to the respective product. In addition to picking up bags from the conveyor system, placing them precisely is often a demanding task - which our gripping systems master reliably.

interface to the conveyor technology

Smooth cooperation between the bag gripper and the conveyor technology is essential for an efficient process. The gripper must be precisely matched to the pitch of the roller conveyor technology, as its tines reach between the individual rollers to pick up the bags. The precise positioning of the bags plays a crucial role here: only when the bags are precisely aligned can they be lifted cleanly and safely. This close coordination between the gripper and the conveyor technology ensures reliable handling and maximum efficiency in the process.

Inquire now or book a starter concept!

Would you like to automate your processes with an efficient and individual solution? We can help you with this – whether with a start-up concept, a tailor-made solution or a complete robot cell.

- Start right away: Book our start-up concept and receive a quick and concrete concept for your requirements.

- Complete solution: Are you looking for comprehensive automation including a robot cell? With our partner network, we will develop a tailor-made complete solution for you that is perfectly tailored to your processes.

Use our contact form , write us an email , or call us directly – we will be happy to advise you personally.

Input data for the design of grippers

In order to optimally adapt the bag gripper to your requirements, certain input sizes and specifications are required. These include:

- Size, weight and nature of the product: The properties of the bags determine the choice and design of the gripper.

- Existing robot: The flange pattern and the maximum payload of the robot must be taken into account.

- Cycle time: The required speed of the process is crucial for the dimensioning and efficiency of the solution.

- MTBF (Mean Time Between Failure): A robust design ensures long operating times and minimizes downtime.

Do you have questions or would you like to talk about a specific project?

Please feel free to call us, send us an email or use the contact form.

Tel: +49 (0) 4121 789 796 - 1

Mail: bjoern@graspmonkey.de

Products from the category "Bag grippers"

-

grasp monkey - gripper for bags

Regular price €5.065,78 EURRegular priceUnit price / per -

grasp monkey - gripper for bags

Regular price €13.845,28 EURRegular priceUnit price / per